In the realm of advanced manufacturing, where precision is paramount, CNC (Computer Numerical Control) machines reign supreme, orchestrating intricate designs with unparalleled accuracy. The secret behind this precision lies in CNC calibration—a meticulous process that fine-tunes these powerful tools to ensure optimal performance. But calibration isn’t a one-time affair; it requires validation to ensure that the achieved results align with the desired outcomes. In this article, we delve into the art of validating CNC calibration results in machining, empowering manufacturers to confirm the accuracy and reliability of their CNC machines.

1. Understanding CNC Calibration: The Crucial Prelude

Before delving into validation, it’s crucial to understand the essence of CNC calibration. Calibration involves aligning and adjusting a CNC machine’s components to ensure that its movements, cuts, and contours are in perfect harmony with the intended design. This precision-driven process is the key to unlocking the full potential of CNC machining.

2. Importance of Validation: Ensuring Precision Beyond Calibration

While CNC calibration is the foundation of accuracy, validation is the compass that ensures the calibration’s effectiveness. Validation is essential to confirm that the calibration results match the intended outcomes, guaranteeing that the CNC machine operates with the desired precision. By validating calibration results, manufacturers can instill confidence in the accuracy of their machines and the quality of their products.

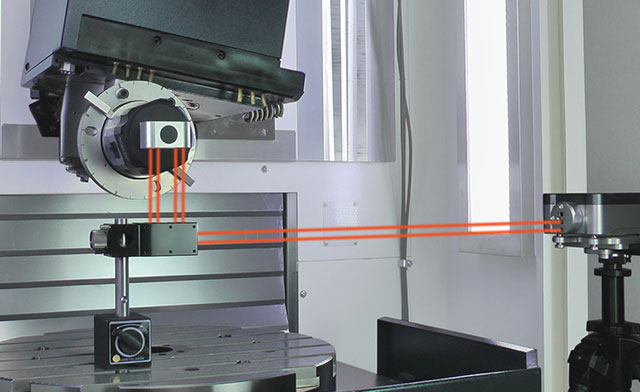

3. Precision Measurement Instruments: The Tools of Validation

To validate CNC calibration, precision measurement instruments take center stage. These tools, such as coordinate measuring machines (CMMs), laser trackers, and optical comparators, are capable of measuring minute dimensional deviations. Utilizing these instruments, manufacturers can compare the actual measurements of machined components to the design specifications, highlighting any variations that may indicate the need for further calibration.

4. Key Steps in Validating CNC Calibration Results

Validating CNC calibration results requires a systematic approach to ensure accurate and reliable measurements. Here are the key steps to guide the validation process:

· Establish Baseline Measurements

Before conducting validation, establish baseline measurements of specific features or dimensions. These measurements serve as reference points for comparison against post-calibration measurements.

· Conduct Post-Calibration Measurements:

After CNC calibration, use precision measurement instruments to measure the same features or dimensions as in the baseline measurements. Compare the post-calibration measurements with the baseline measurements to identify any deviations.

· Analyze Deviations and Trends

Analyze the deviations between the baseline and post-calibration measurements. Are the deviations within acceptable tolerances? Are there any consistent trends indicating areas that may require further attention? This analysis guides the decision-making process moving forward.

· Adjust and Fine-Tune Calibration

If deviations are detected outside of acceptable tolerances, it may be necessary to adjust and fine-tune the CNC machine’s calibration. This iterative process ensures that the machine achieves the desired level of precision.

· Revalidate and Verify

After making calibration adjustments, revalidate the results using the same measurement instruments and methodology. This step confirms that the adjustments have successfully addressed any deviations.

5. Importance of Documentation: Preserving Calibration Integrity

Thorough documentation is an integral part of the validation process. Document baseline measurements, post-calibration measurements, deviations, adjustments, and revalidation results. A well-documented validation process ensures transparency, traceability, and accountability, enabling manufacturers to maintain the integrity of calibration efforts.

6. Leveraging Advanced Software Solutions: Streamlining Validation Workflow

Advancements in technology have introduced sophisticated software solutions that streamline the validation process. These software tools facilitate data collection, analysis, and reporting, making the validation workflow more efficient and accurate. Manufacturers can harness these tools to enhance the validation process and ensure comprehensive documentation.

7. Continuous Improvement and Ongoing Validation

CNC calibration and validation are not one-time events but ongoing processes. As CNC machines evolve and encounter various operational conditions, regular validation becomes crucial to maintain precision. Manufacturers should establish a regular validation schedule, conduct routine checks, and make necessary adjustments to ensure consistent and reliable performance.

Precision Validated, Excellence Ensured

In the intricate dance between precision and validation, CNC calibration emerges as the choreographer that shapes the art of machining. Validating CNC calibration results is the compass that guides manufacturers toward the pinnacle of accuracy, ensuring that each product crafted is a masterpiece of precision and quality. By understanding the significance of validation, leveraging precision measurement instruments, following a systematic validation process, documenting meticulously, and embracing technological advancements, manufacturers can navigate the path to excellence, producing products that embody the epitome of precision and craftsmanship.