If you are looking to ensure the longevity and efficiency of your CNC machines, proper maintenance is the key. CNC machining play a pivotal role in modern manufacturing, providing precision and automation that significantly enhance productivity. To maximize the performance and lifespan of these machines, a well-structured maintenance routine is essential. In this article, we will delve into the critical aspects of maintaining CNC machining for optimal performance. Additionally, we will introduce you to Exact Machine Service, Inc, a reputable distributor of top-quality new and used CNC machine tools, manual machine tools, parts, and accessories. With their expertise, you can keep your CNC machining in prime condition, ensuring uninterrupted production and superior output.

Understanding CNC Machine Maintenance Basics

Maintaining a CNC machine involves a combination of preventive measures and regular inspections. The complex nature of these machines requires a comprehensive approach to ensure all components are in top shape. Regular cleaning, lubrication, and inspection of crucial Lubrication plays a crucial role in parts such as ball screws, linear guides, and spindles are fundamental to prevent wear and tear.

Lubrication: A Key Element of CNC Machine Care

preventing friction-related issues that can lead to machine breakdowns and compromised precision. CNC machining consist of numerous moving parts that require proper lubrication. The type and frequency of lubrication depend on the machine’s design and usage. Regularly inspecting lubricant levels and replacing them when necessary is essential for optimal performance.

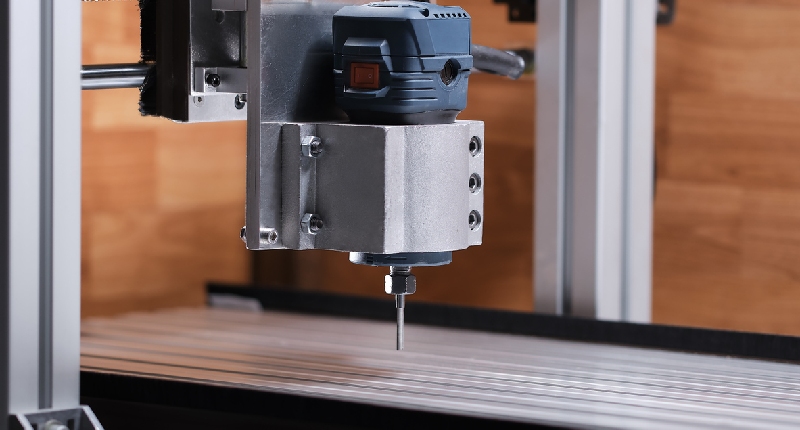

Tooling Maintenance and Calibration

The accuracy of a CNC machine heavily relies on its tooling system. Regularly inspecting and calibrating tools is imperative. Dull or misaligned tools can result in poor quality cuts and increased stress on the machine. A well-maintained tooling system not only ensures precise results but also reduces the load on the machine, prolonging its lifespan.

Electrical Component Inspection

The electrical components of a CNC machines are sensitive and prone to wear over time. Loose connections, damaged wires, and faulty sensors can lead to erratic performance or sudden breakdowns. Regularly inspecting and tightening electrical connections, cleaning dust and debris, and replacing damaged components can prevent these issues.

Software Updates and Backups

In the digital age, CNC machines rely heavily on software for programming and operation. Keeping the machine’s software up-to-date is crucial to take advantage of the latest features and security patches. Additionally, regularly backing up your machine’s programs and settings can help in case of unexpected failures or crashes.

Environmental Factors and Machine Placement

The environment in which a CNC machine operates can significantly impact its performance and longevity. Dust, temperature fluctuations, humidity, and vibrations can all affect the machine’s precision and reliability. Properly housing the machine in a controlled environment and implementing measures to mitigate these factors can go a long way in ensuring optimal performance.

Enlisting Professional Expertise – Exact Machine Service, Inc

Maintaining a CNC machine involves intricate knowledge of its mechanics and technologies. This is where Exact Machine Service, Inc comes into play. As a reputable distributor of quality new and used CNC machining tools, manual machine tools, parts, and accessories, they possess the expertise to assist you in maintaining your CNC machines for optimal performance. Their team of skilled professionals can provide guidance on maintenance routines, recommend appropriate parts, and offer solutions to any machine-related challenges.