The use of aluminium powder coating has transformed the metal closing industry. This ground-breaking method has completely changed the way they preserve alongside improved aluminum surfaces, as well as it has many advantages that go well beyond aesthetics. Across a wide range of industries alongside applications, powder coating has displayed its value because of its durability as well as environmental friendliness. They look at the various benefits of aluminum powder coating in this post, which will help explain why so many manufacturers, designers, in addition to customers now choose it.

1.Unmatched Durability

The wonderful longevity of aluminum powder coating is one of its main advantages. In variation to regular liquid paints, powder coating produces a strong, long-lasting layer that is resistant to weather in addition to aging. The durable coating effectively prevents chipping, scratches, alongside fading, guaranteeing that aluminum objects retain their integrity and aesthetic appeal for an extended period.

The application procedure holds the key to success. Particles of powder that are electrostatically charged are sprayed over the aluminum surface and baked at a high temperature. The powder melts as well as flows due to the heat, creating a similar, seamless covering that firmly adheres to the metal. As a result, the finish is much stronger than traditional paint, able to withstand adverse weather, UV rays, alongside normal wear and tear.

The lower maintenance costs along with longer product lifespan associated with this durability apply to outdoor furniture, architectural elements, and vehicle parts. The longer lifespan of powder-coated aluminum products benefits homeowners, companies, as well as industries alike, making it an economical long-term investment.

2. Superior Corrosion Resistance

Although aluminum has a natural acceptance to corrosion, powder coating increases this resistance even more. Aluminum is resistant to declining over time from corrosive substances, chemicals, as well as moisture because of the thick, continuous layer that powder coating creates.

This improved resistance to corrosion is especially useful near the seaside, where untreated metal surfaces can be rapidly eroded by salt spray. Compared to uncoated or conventionally painted aluminum, powder-coated aluminum can endure these harsh environments along with keeping its structural integrity and aesthetic appeal for an important longer period of time.

This capability is very helpful to the transportation, construction, and marine industries. Boats, building fronts, alongside car parts subjected to extreme weather can maintain their quality and performance over long stretches of time, lowering the frequency of replacements as well as repairs.

3. Eco-Friendly Finish

Compared to conventional liquid paints, powder coating is a more environmentally responsible option in a time when environmental awareness is crucial. Little charged organic compounds (VOCs), which are bad for the environment as well as for human health, are produced by this procedure.

There is almost little waste because the powder particles don’t contain any solvents in addition to any overspray that may be recovered alongside. This lessens the impact on the environment and improves worker safety for those who perform coating operations.

Additionally, the durability of powder-coated surfaces implies that aluminum products won’t need to be painted or replaced as frequently. Over time, this decrease in waste and material consumption leads to a lower environmental footprint, which is consistent with green building requirements and sustainable practices.

4. Cost-Effective Solution

Although powder coating may initially cost a little more than conventional painting techniques, in the long run, it works out to be a more affordable option. Powder-coated surfaces last longer alongside require fewer touch-ups, paint jobs, and replacements of aluminum items because of their resilience.

Liquid painting is less efficient than the application method itself. Full coverage can be obtained with powder coating in one application, while liquid paints frequently need several applications. This efficiency, particularly in large-scale manufacturing processes, translates into reduced labor costs and faster production times.

Additionally, recycling overspray powder lowers material waste, which saves money even more. Powder-coated aluminum goods are an economical option for both individuals and businesses due to their lower replacement and maintenance expenses over time.

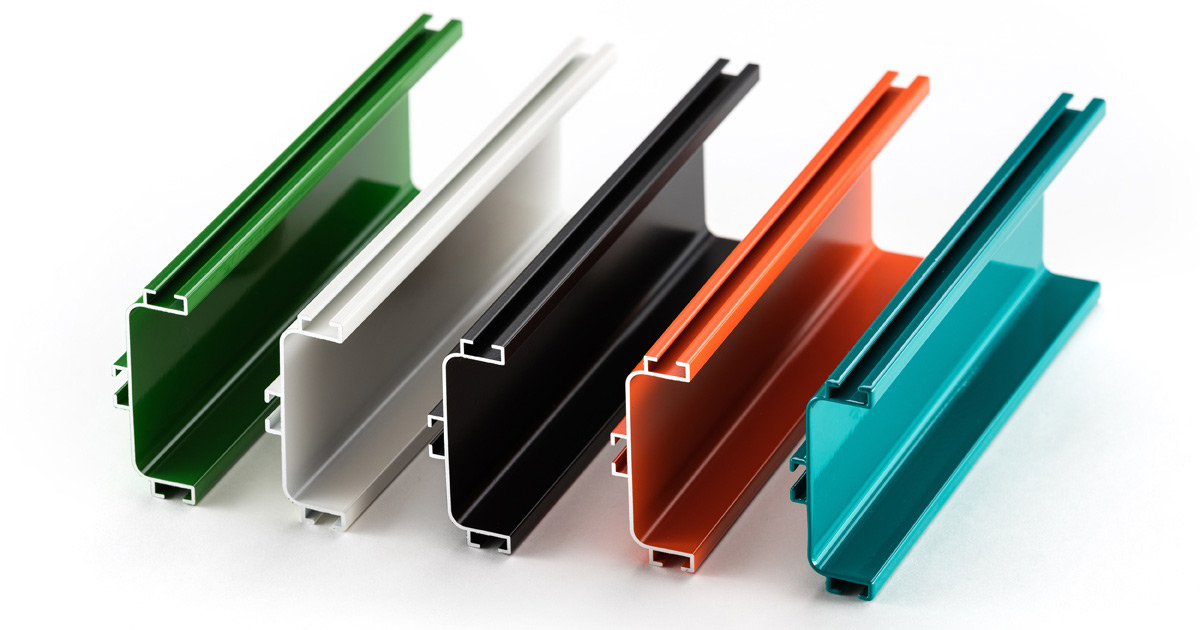

5. Versatile Aesthetic Options

An amazing variety of colors, textures, alongside finishes are available for powder coating, giving aluminum surfaces unmatched customizability. The options are endless, ranging from bold colors to fine metallics, high-gloss to matte finishes, along with smooth to textured surfaces.

Because of its adaptability, powder coating is a great option for designers in addition to architects who want to accomplish certain aesthetic objectives. Powder coating may satisfy a variety of design needs, whether it’s giving outdoor structures a water resistant finish to indoor furnishings a smooth, current appearance.

Using unique colors along with finishes is advantageous for branding initiatives as well. Aluminum goods make it simple for businesses to match their brand colors, guaranteeing uniformity in a range of uses, from signage to equipment.

6. Uniform and Flawless Finish

The ability of powder coating to leave aluminum surfaces with a smooth, uniform finish is one of its distinguishing features. The powder particles are distributed uniformly across the surface, even in difficult-to-reach places and intricate shapes, thanks to the electrostatic application technique.

The powder melts when heated and flows smoothly, producing a continuous film devoid of the runs, drips, and sags that are sometimes seen in liquid paints. This produces a polished surface and precisely uniform coating thickness, improving the overall quality and appearance of aluminum items.

Powder coating consistency is especially useful for mass-produced goods where uniformity is essential. This immaculate finish raises the perceived worth and quality of the final product, which includes consumer electronics and automotive components.

Conclusion

Powder coating aluminum has several a-in addition to visible advantages. Powder coating has become the go-to finishing technique for aluminum surfaces because of its beyond compare toughness, resistance to corrosion, affordability, alongside eco-friendliness.

They may anticipate even more breakthroughs in powder coating compositions as well as application methods as technology develops, which will increase the product’s potential alongside advantages. Choosing aluminium powder manufacturers in india is a wise investment in terms of sustainability, longevity, as well as quality for both businesses along with consumers.