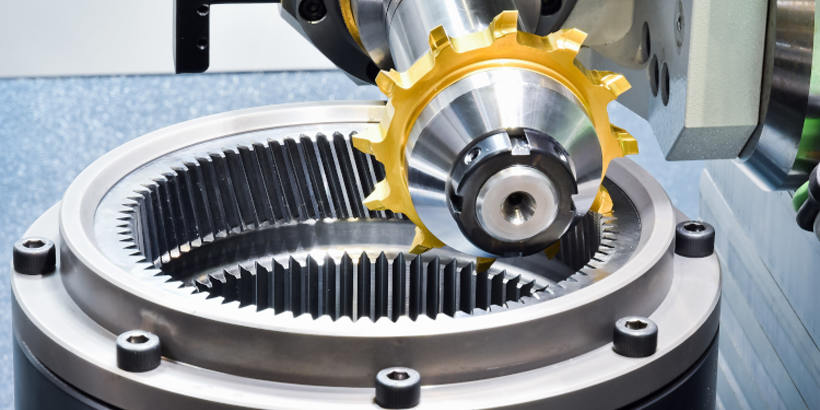

In the world of manufacturing, gear-cutting tools play a crucial role. The gears in all the machines work so accurately because of these tools. Gear-cutting tool manufacturers have the attention of all industries as they innovate tooling solutions.

This article delves into the world of gear-cutting tooling, its benefits, and its impact on the modern world.

Advantages of Gear Cutting Tools

Unparalleled Precision:

Gear cutting tools are meticulously designed and crafted to achieve the highest levels of precision. Their intricate shapes and sharp edges allow for the creation of gears with accurate tooth profiles, ensuring seamless interaction between meshing gears. This precision contributes to the reduction of friction, noise, and wear, ultimately enhancing the longevity of gear systems.

Enhanced Efficiency:

The utilization of advanced gear cutting tooling techniques optimizes the manufacturing process, resulting in enhanced efficiency. Computer Numerical Control (CNC) technology, for instance, enables automated and consistent gear production, reducing human error and increasing production output. This not only accelerates manufacturing but also maintains uniformity across batches.

Versatility:

Gear cutting tools manufacturers cater to a diverse range of industries, accommodating varying gear sizes, types, and materials. Bevel gears for automotive applications, helical gears for industrial machinery, and worm gears for heavy-duty equipment – all benefit from the tailor-made precision these tools offer. This versatility ensures that manufacturers can source the right tools for their specific needs.

Innovation in Materials:

Modern gear cutting tooling has transcended traditional limitations by incorporating innovative materials. High-speed steel, carbide, and even advanced ceramics are employed to construct these tools, enhancing their durability and wear resistance. This innovation directly impacts the quality of gears produced and extends the service life of the tools themselves.

Unveiling the Impact

The presence of top-notch manufacturers is pivotal in shaping industries across the globe. These unsung champions enable the production of gears that are the very backbone of machinery, facilitating the smooth functioning of numerous sectors. From the precision required in aerospace applications to the robustness needed in heavy construction equipment, gear cutting tools ensure that every cog turns seamlessly.

Industries that rely on gear-based machinery understand the significance of impeccable gear production. The aerospace sector, for instance, relies on gears for flight control systems and landing gear mechanisms, where precision is paramount. Similarly, the automotive industry thrives on gear-based transmissions and engine components. In all these applications, the role of gear cutting tools cannot be overstated.

Conclusion

As the curtain rises on the realm of manufacturing, manufacturers take their well-deserved place in the spotlight. Their dedication to precision, efficiency, versatility, and innovation forms the foundation upon which industries build their future. In the heart of every machinery’s rhythmic hum lies the perfection carved by these tools, ensuring that the gears of progress continue to turn smoothly.

In conclusion, the journey from raw materials to intricately crafted gears is guided by the prowess of gear cutting tooling. This often-underestimated aspect of manufacturing showcases its significance through the advantages it brings and the impact it creates across diverse sectors. With manufacturers constantly pushing the boundaries of excellence, the manufacturing landscape stands poised for a future defined by precision and efficiency.