Short for Computer Numerical Control, these machines have revolutionized industries by providing high precision, efficiency, and consistency in various manufacturing processes. CNC machines are utilized across a wide array of industries, from automotive and aerospace to electronics and medical device production. This article delves into the various types of CNC machine, their applications, and how they have reshaped the manufacturing landscape.

Types of CNC Machines

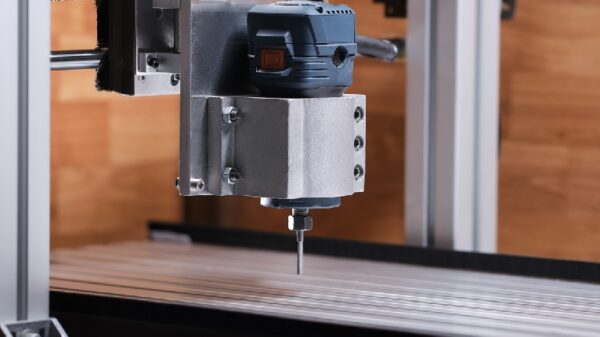

- CNC Milling Machines: One of the most common types of CNC machines is the CNC milling machine. These machines use rotary cutters to remove material from a workpiece, resulting in precise and complex shapes. CNC milling machines are highly versatile and find applications in industries ranging from metalworking to woodworking. They can produce intricate components and parts with tight tolerances.

- CNC Lathes CNC: lathes are used for cylindrical machining operations. They rotate the workpiece while a cutting tool shapes it into the desired form. CNC lathes are invaluable in producing symmetrical parts like shafts, bolts, and fittings. They come in various configurations, including vertical and horizontal lathes, each with its own advantages for specific applications.

- CNC Plasma Cutters: CNC plasma cutters use a focused jet of hot plasma to cut through materials like metal, steel, and aluminum. These machines are commonly used in industries that require precise metal cutting, such as automotive fabrication and construction. CNC plasma cutters enable intricate designs and shapes to be cut with high precision.

- CNC Laser Cutting Machines: Similar to plasma cutters, CNC laser cutting machines use a high-powered laser beam to cut through materials. These machines are renowned for their accuracy and speed, making them essential in industries that demand intricate cuts, such as aerospace and electronics. They are capable of cutting a wide range of materials, including metals, plastics, and even ceramics.

- CNC Routers: CNC routers are employed for engraving, cutting, and shaping materials like wood, plastics, and composites. They are extensively used in industries like woodworking, signage, and prototyping. CNC routers can create detailed designs and patterns on flat surfaces, adding a new dimension of creativity to manufacturing processes.

- CNC 3D Printers: A recent innovation in the world of CNC machines is CNC 3D printers. These machines use additive manufacturing techniques to build three-dimensional objects layer by layer. They have revolutionized rapid prototyping, allowing designers and engineers to quickly transform digital designs into physical objects. CNC 3D printers find applications in various industries, from aerospace to healthcare.

Applications of CNC Machines

The versatility of CNC machines translates into a multitude of applications across diverse industries:

- Automotive Industry: CNC machines are used to manufacture intricate engine components, transmission parts, and body panels with high precision. They enable efficient mass production while ensuring consistency and quality.

- Aerospace Industry: In aerospace, where precision and reliability are paramount, CNC machines are used to create complex components like turbine blades and aircraft structural parts. These machines contribute to the lightweighting and fuel efficiency of modern aircraft.

- Medical Industry: CNC machines are pivotal in the production of medical devices and implants. From orthopedic implants to dental prosthetics, these machines craft components that require exact dimensions and biocompatibility.

- Electronics Industry: CNC machines are integral to the production of circuit boards, connectors, and microelectronics. They enable the creation of intricate designs on small scales, contributing to the advancement of technology.

- Art and Design: Beyond industrial applications, CNC machines have found a place in the world of art and design. Artists and designers utilize these machines to create intricate sculptures, furniture, and decorative pieces that blend technology and creativity.

Advantages of CNC Machines

The adoption of CNC machines offers numerous advantages:

- Precision and Accuracy: CNC machines deliver unparalleled precision and accuracy, ensuring that each product adheres to strict dimensional requirements.

- High Efficiency: Automation in CNC machines leads to increased production efficiency, reducing the time and labor required for manufacturing processes.

- Consistency: CNC machines eliminate variations caused by human error, resulting in consistent product quality across batches.

- Complex Geometries: These machines can produce complex and intricate geometries that would be nearly impossible or extremely time-consuming to achieve manually.

Conclusion

CNC machines have ushered in a new era of manufacturing, transforming industries and pushing the boundaries of what is possible. From CNC milling machines that craft intricate parts to CNC 3D printers that bring digital designs to life, these machines continue to shape the modern world. The versatility, precision, and efficiency of CNC machines make them an indispensable asset across a wide range of applications. As technology advances, we can only anticipate further innovations in CNC machines, propelling industries into a future defined by precision and automation.