Accuracy and effectiveness are crucial in the manufacturing sector. The precision of procedures has a major bearing on the quality of output in many industries, from building to manufacturing. Pipe cutting and beveling are two examples of areas where accuracy is essential. Several industries have benefited greatly from the development of cold pipe cutting and bevelling equipment. Know more about cold pipe cutting and bevelling machine.

Pipe Beveling and Cold Cutting Machines: A Primer

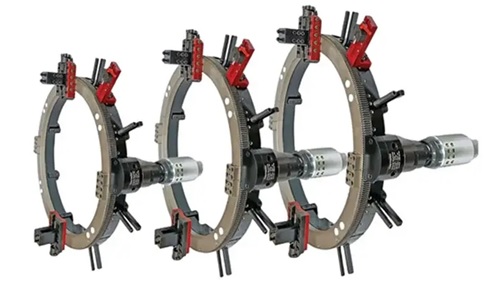

Pipes may be cut and bevelled with extreme accuracy and minimum waste heat using modern cold pipe cutting and bevelling devices. Cold pipe cutters use a cold-cutting procedure as opposed to the conventional methods that rely on heat-based cutting processes. Cutting pipes using revolving blades eliminates the need for high temperatures, which can cause deformation or damage to the material. Learn more about cold pipe cutter machine.

The Value of Pipe-Cutting and Beveling Cold Equipment

- Cold pipe cutters are renowned for their pinpoint accuracy. Regardless of the thickness of the material being cut, clean and precise cuts may be made using a cold-cutting method. In fields where even a centimetre off in measurement can mean wasted time and money, this level of accuracy is essential.

- Cold pipe cutting and bevelling equipment do not use any heat during the cutting process, unlike conventional procedures. Because of this, the pipe’s integrity is maintained, and workers are less likely to be exposed to dangerous sparks or flames.

- Pipes made of steel, stainless steel, copper, and other materials are no problem for this equipment. Because of their adaptability, they may be used in a wide range of fields, including construction and the oil and gas sectors.

- Time and money savings may be realised via the use of cold pipe cutting and bevelling devices due to their precision and speed. This means more efficiency and savings for enterprises.

- Less Material Is Wasted Thanks to the Accuracy of Cold Cutting, Less Material Is Wasted. Since the material is not warped by heat during the cutting process, less of it goes to waste.

- Cold pipe cutters are made to be simple to use and just require basic instruction to use. Because of how simple it is to use, it can be implemented in many settings quickly.

Uses for Pipe Beveling and Cold Cutting Equipment

- Cold pipe cutting and bevelling equipment have a wide range of uses across several sectors.

- To enable good fitting and welding in pipeline building projects, precision pipe cutting and bevelling are required. By simplifying these steps, cold pipe cutters boost the productivity of building sites.

- The precision of cold pipe cutting and beveling is useful in manufacturing for industries that use pipes as parts of their products. Products in the automotive, aerospace, and machinery manufacturing industries benefit from the use of these equipment.

Finally, cold pipe cutting and bevelling devices have become indispensable in sectors that place a premium on accuracy, productivity, and worker safety. Their accuracy, low heat output, adaptability, and low cost make them a desirable choice for many different kinds of uses.